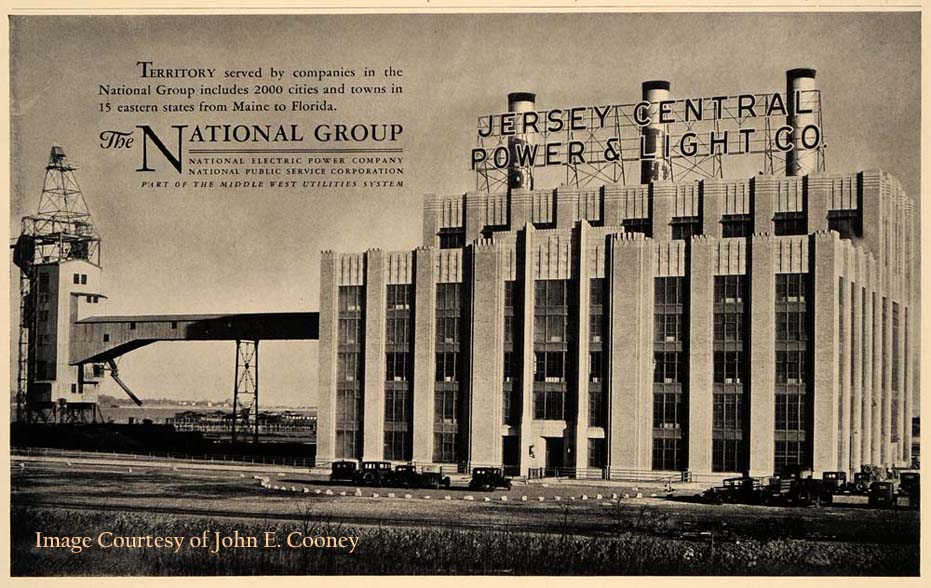

1930’s Advertisement for the Newly Opened State-of-the-Art Jersey Central Power & Light Power Plant in South Amboy, NJ. Photo Courtesy of John E. Cooney via Diane Norek Harrison, Author of “Remembering the Past” on NJToday.net.

On my 2012 trip to the Morgan and South Amboy area, I reconnected with my school friend Ken. After we visited the Conference House on Staten Island, we drove through South Amboy and noticed the old Jersey Central Power & Light Company’s power plant had coverings over its seven or eight stories of windows. This power plant facility provides electricity to next door Morgan. This area has long been a place of interest to Ken who used to ride his bike to this area as a kid to check out the coal pier when it was there. A security guard at the plant indicated that they were in the process of asbestos removal before the planned demolition in 2013.

The E. H. Werner Power Plant in South Amboy, NJ as seen from the Beach in front of Staten Island’s Historic Conference House in August 2012.

Like so many other things about Morgan, this set me wondering about the history of this plant. It is a very hard building to not notice. You can see it from Staten Island, Perth Amboy, and from the railroad tracks in Morgan. Heck, I wouldn’t doubt that you can see it from Coney Island all the way across Raritan Bay. If you are next to the railroad tracks at the end of Old Spye Road in Morgan and look under the Route 35 bridges toward South Amboy, you can’t miss seeing it even though it is 2.25 miles away.

Thanks to the on-line back issues of South Amboy Citizen available via the South Amboy Sadie Pope Dowdell Public Library web site and the Matawan Journal available via the Matawan Public Library web site, I was able to find out a lot of information about the history of the plant. I also learned something very surprising. It wasn’t until I looked at some photos I took of the plant in 2005 that I noticed how interesting the architecture of it really was – this lead to another visit and some closer photos in 2008.

According to one of the on-line articles, this building was designed by the same architects who designed the Empire State Building! Rather than digesting the on-line info and repackaging it, I took the approach of highlighting some items of interest below and including most of the text from the on-line materials along with a link to them.

- Construction of the $6,500,000 plant started sometime in early 1929 by the Jersey Central Power & Light Company (JCP&L).

- The plant was built on swamp land which was filled in with thousands of yards of sand.

- The plant was centrally located at the mouth of the Raritan River, adjacent to rail, highway and water transportation for fuel and supplies.

- JCP&L, according to a speech given by Thomas R. Crumley, President of the JCP&L, at the time of the dedication of the plant, was formed in March 1925 and represented a consolidation of eight companies. Between that date and the dedication, twelve other companies had been acquired, most of them during 1926 and 1927.

- The original plant was composed of the portion of the building under the three smoke stacks. The taller section was added over 20 years later! This discovery was very surprising as the extension was implemented so seamlessly that you just can’t see any evidence of it.

- The first portion of the plant was dedicated on October 31, 1930 at which time New Jersey Governor Morgan (!) F. Larson threw a switch which formally put the plant into service.

- At the dedication ceremony, some 300 guests were served a buffet luncheon in railroad dining cars on a siding within the plant yard.

- The plant had an initial power generation capacity of 50,000 kilowatts from two 25,000 kilowatt turbo generators. There was space for a third 25,000 kW generator between the two other generators.

- The boilers were supplied by Babcock & Wilcox, the company which also supplied boilers for the battleships of President Teddy Roosevelt’s “Great White Fleet.”

- The plant was initially capable of supplying electric light and power for 253,000 people.

- The plant was featured on twelve pages in the July 1930 issue of Power Plant Engineering (anyone know how to get access to this?). There were fifteen photographs and seven drawings along with “a very complete compilation of data relating to the local plant.”

- Electric Management and Engineering Corporation was the general contractor, along with thirteen subcontractors, for a total work force of about 300 men.

- During construction, a neon-gas sign was erected on top of the building which was one of the largest in the state and visible for miles away.

- The plant output three voltages of current: 13,000; 33,000 and 66,000.

- Two transmission lines were initially constructed to connect the plant to other sections of the state.

- Seven miles of steel tower transmission lines leading from South Amboy into the southern territory of the company became energized with the opening of the new plant.

- Twenty-six miles of steel tower transmission lines connected with Jersey Central’s generating station at Whippany, in Morris County.

- The power lines to Whippany traversed over the former site of the Stevensdale Institute and Estate. This power line right-of-way, and possibly the same power lines, are still present over this site.

- The article had some information regarding the plant’s architecture: “Both interior and exterior of the South Amboy station present a most pleasing appearance. As shown in the headpiece, the building design is simple; it is dependent on two principal masses, with good fenestration. The vertical lines of the pilasters, the conservative decoration at the top of each pilaster and the continuous horizontal lines of the stone trim at the top all contribute their parts to the total satisfactory effect. The station is of light buff face brick and steel construction. As evident, the wall space between pilasters is practically all window, providing splendid lighting and ventilation. This is especially noticeable in the boiler room where the absence of overhead bunkers permits full advantage to be taken of the windows and the monitor over the firing aisle. The interior of the boiler room is left in the original light colored brick of the building walls. In the turbine room, however, an unusually pleasing appearance is obtained by rows of dark brown tile. The turbine room floor is of brown tile.”

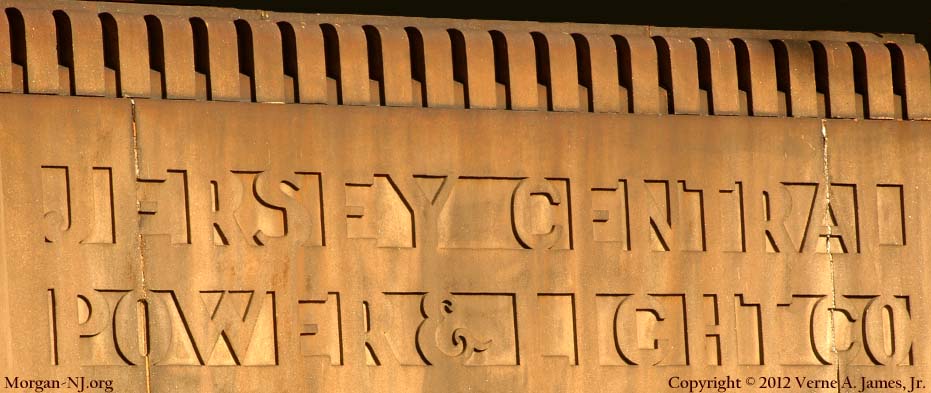

Iconic Art Deco Inspired Jersey Central Power & Light Inscription over the 1930’s Front Entrance of South Amboy’s E. H. Werner Power Plant in May 2008.

- Over the door of the building is the name of the company embedded in the concrete in art deco inspired lettering.

- The plant was originally powered by coal which was brought in on barges and stored on the south side of the building in a giant coal yard.

- As shown in the photograph provided by John E. Cooney via Diane Norek Harrison, author of “Remembering the Past” on NJToday.net, there used to be a tower on Raritan Bay which would be used to empty coal from the barges.

- The coal would be automatically conveyed to the power plant where it would be pulverized into fine talcum-like powder and fed into the burners beneath the 1,400 pounds per square inch boilers to generate the steam which would turn the two 25,000 kilowatt turbo generators. The ashes were taken out, unseen, by suction and the slag, heated to a high temperature, turned liquid and ran off in pipes like waste water.

- Even in 1930, the plant was so automated that there were relatively few people needed to run it.

- In this original two generator configuration, the plant consumed 175,000 tons of coal per year, enough for a city of 100,000 people and 84,000 gallons of water per minute – more than the supply of the city of Cleveland.

- There was room between the two generators to add a third one though that never occurred at that exact location.

- The initial capability of 50,000 kilowatts was somehow expanded sometime before World War II to 55,000 kilowatts.

- The plant survived the nearby May 19, 1950 “Powder Pier” explosion where 600 tons of munitions loaded on a barge ignited 550 yards from the plant. Sadly 31 dock workers were killed. Some 2,300 live anti-personnel mines were blown into the plant and on its property. Fifteen JCP&L workers were on duty at the time of explosion. Although many were injured or concerned about their families, all stuck to their posts and shut down the plant to prevent further damage. These 15 employees were presented The Claude L. Matthews Award for Valor by the Edison Electric Institute for “extraordinary courage.”

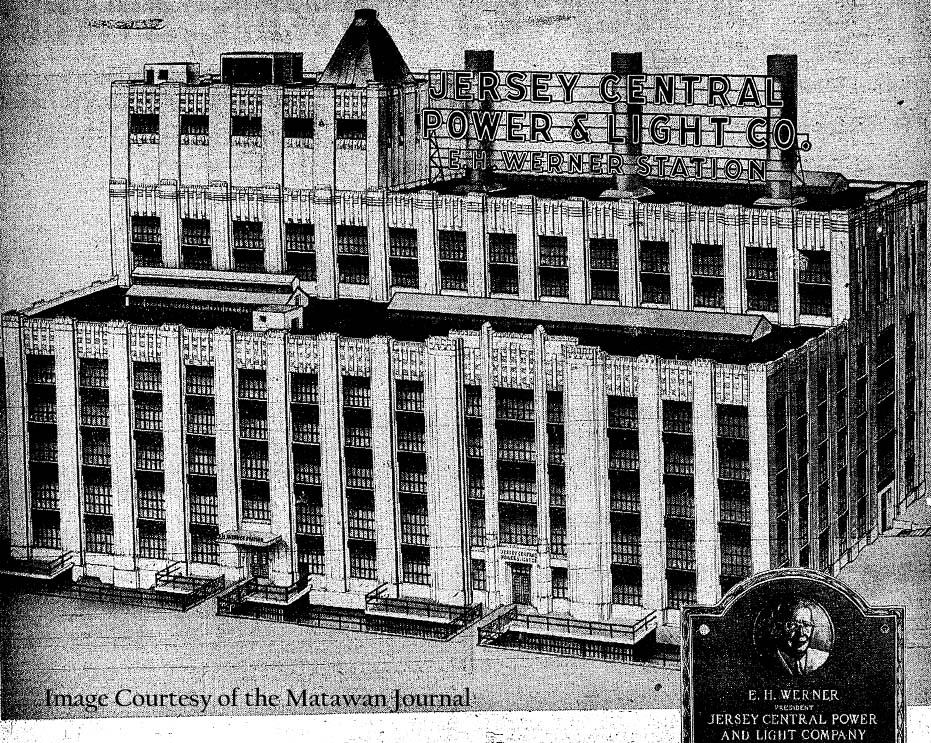

Illustration of the Newly Expanded E. H. Werner Power Plant and Portion of the E. H. Werner Plaque from the June 11, 1953 Matawan Journal.

After World War II, a $12,500,000 extension to the plant, which started in 1950, opened on Friday, June 12, 1953. It incorporated a new 62,500 kilowatt turbo-generator of the latest design; Cyclone furnaces, pressurized boiler and its auxiliary equipment; and new coal-conveying and crushing system. To incorporate this new generator, the building was extended toward Raritan Bay – this is the portion of the building which is taller than the other portion. Again, if you looked closely at the section where the extended portion of the building was added, you would see absolutely no evidence of the extension other than that it was taller. Amazing brickwork and architectural flares!

At the time of the dedication, the plant was renamed to the E. H. Werner Station in honor of E. H. Werner, the president of JCP&L, for his 41 year utility career including 8 as JCP&L president. Mr. Werner’s granddaughter unveiled the plaque, housed in the station’s lobby, which read “E. H. Werner President Jersey Central Power and Light Company. For whom this station is named. His outstanding ability and leadership in the electric industry has furthered the high ideal of greater service to the public and community.” I imagine this plaque is still in the lobby and wonder what will happen to it when the building is demolished.

- The plant site covered 28 acres and was designed to burn either coal or oil with an estimated coal consumption for one year, including the new addition, of 270,000 tons.

- This was the site of the first installation of the newly designed Babcock & Wilcox Cyclone Furnace-Fired Radiant Boiler on the eastern seaboard. Cyclone powered boilers differ from the previous pulverized coal-fired furnaces in how the air is circulated within the boiler, i.e., like a cyclone.

- The boiler was fired by two Cyclone furnaces.

- The turbine-generator was built by General Electric.

- Jersey Central Power & Light entered into an expansion program after World War II to try to stay ahead of the rapid growth. It was during this time that the WWII veterans were home, having families and the housing boom was in progress.

- JCP&L decided to add to the South Amboy plant because of its location in the center of the company’s territory, the accessibility to fuel and water, and the existence of facilities, including intake discharge for condensing water and an existing coal-unloading tower.

- A ten-mile maze of pipe work, exclusive of the boiler, had to be put in place for steam and water.

- Approximately 100 miles of electrical cable was necessary to tie all of the equipment together to form the compact automatic unit.

- 6,500 cubic yards of concrete, enough to lay a sidewalk from South Amboy to Long Branch, was mixed and poured.

- A 1,200 ton coal bunker capable of holding a fifty-four hour supply of fuel was installed.

- The massive boiler costing $1,300,000 was set into place, with the main drum alone weighing 68 tons.

- Hundreds of pipes, some over 100 feet long, were attached in the boiler to the upper and lower drums. Each piece of pipe was numbered and calibrated to fit exactly in its proper opening in the drums. Men skilled in boiler construction welded and hammered day after day as the huge boiler slowly took shape.

- Air heaters made up of ten thousand tubes, 52 feet and 16 feet long, were scientifically assembled. If laid end to end, these tubes would extend over 68 miles.

- Every welded joint was X-rayed.

- The turbine spindle and rotor, possessing hundreds of precision made blades, was raised by a crane and moved across the plant floor level. It was then lowered inch by inch under the expert eye of the engineers into the recesses provided in the base of the unit. This operation took tedious time and thorough control so damage would not occur.

- On the first power up test, enough electricity was produced by the unit in one hour to serve the average residential customer for 34 years.

- Unlike the original boilers, which required the coal to be pulverized into flour-like powder, the new boiler only required it to be crushed to one-quarter of its size in comparatively simple crushers.

- The furnaces are lined with miles of water filled tubes. The heat from the burning coal converts the water into steam which enters the turbine-generator at great speed.

- The temperature of the steam can be as high as 1,000 degrees F and blows at 1,200 miles an hour against the curved blades of the turbine at 1,650 pounds per square inch of pressure.

- The spinning turbine is directly connected to the generator’s rotor. The spinning of the rotor within the generator’s stationary copper coils is what generates the electricity.

- The 62,500 kilowatt turbo-generator weighs 745,000 pounds.

- In the basement of the plant, the boiler feed pumps force water to the boiler tubes against terrific steam pressure and circulate millions of gallons of water every day. In 26 minutes, the pumps will circulate enough water for the daily consumption of a city of approximately 17,000 persons.

- After opening with the new generator, the E. H. Werner Station became the largest of the three electric generating plants of the Jersey Central Power & Light Company at 117,500 kilowatts. The other two being Whippony at 20,000 kilowatts and Sayreville at 100,000 kilowatts.

- Each day, the plant had three eight-hour shifts.

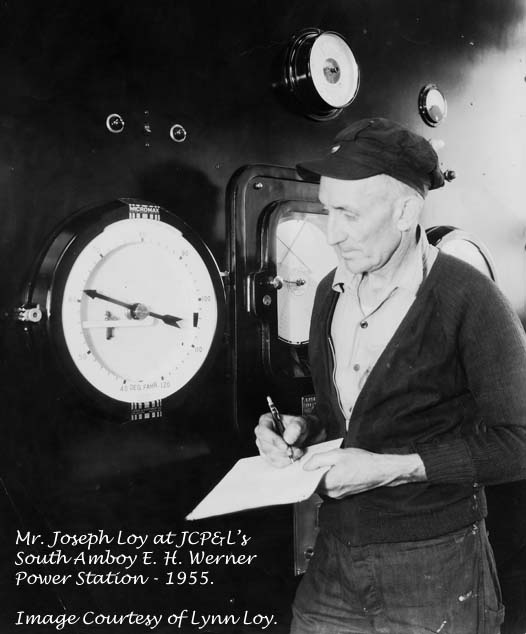

- The June 11, 1953 Matawan Journal lists two Morgan residents as employees of the plant: Shift Foreman Joseph Loy and Plant Maintenance Crew Head Norman Nelson.

Lynn Loy, daughter-in-law of Joseph Clifford Loy and longtime Morgan resident, was kind enough to send me some biographical information about Mr. Loy as well as some photos of him and Mr. Norman Nelson. Mr. Loy was born in Bethel Township (New Carlisle), Ohio in 1890 – between Dayton and Springfield. As a young adult, he was an Engineer on the Ohio & Pennsylvania Railroad before joining the Army for three years starting just after World War I at age 29. While in the Army, Mr. Loy achieved the rank of Sergeant and spent time in Germany at Blick auf Montabaur mit Schloss then later was in charge of the Emergency Pumping Station at Camp Dix. After leaving the Army, Mr. Loy spent four years as a 1st Class Engineer and Assistant to the Power Plant Superintendent at Lakehurst Naval Air Station. Sometime in 1926, Mr. Loy became an employee at the recently formed Jersey Central Power & Light Company ultimately moving to Dolan Avenue and working at the South Amboy plant where he retired after 30 years of service to JCP&L in 1956. Mr. Loy passed away in January of 1966.

Lynn Loy, daughter-in-law of Joseph Clifford Loy and longtime Morgan resident, was kind enough to send me some biographical information about Mr. Loy as well as some photos of him and Mr. Norman Nelson. Mr. Loy was born in Bethel Township (New Carlisle), Ohio in 1890 – between Dayton and Springfield. As a young adult, he was an Engineer on the Ohio & Pennsylvania Railroad before joining the Army for three years starting just after World War I at age 29. While in the Army, Mr. Loy achieved the rank of Sergeant and spent time in Germany at Blick auf Montabaur mit Schloss then later was in charge of the Emergency Pumping Station at Camp Dix. After leaving the Army, Mr. Loy spent four years as a 1st Class Engineer and Assistant to the Power Plant Superintendent at Lakehurst Naval Air Station. Sometime in 1926, Mr. Loy became an employee at the recently formed Jersey Central Power & Light Company ultimately moving to Dolan Avenue and working at the South Amboy plant where he retired after 30 years of service to JCP&L in 1956. Mr. Loy passed away in January of 1966.

Circa 2012 Bing.com Birds Eye Aerial View of South Amboy’s Electrical Power Plant Complex at the Mouth of the Raritan River at Raritan Bay. The Obsolete Coal Powered E. H. Werner Power Plant has been replaced by the Four Oil Powered Generators.

In 1972, four 53 megawatt oil-fuel simple-cycle combustion turbines began operations. The two original 1930 steam generators were retired in 1976 and the one 1953 steam generator was retired in 1996. Another way of looking at it is one 53 megawatt generator (53,000 kilowatts) was nearly the same capability as the 1930’s era 50,000 kilowatt generator. Combined these four 53 megawatt generators produce 112 megawatts. The combined output from the 1930 and 1953 generators was 117.5 megawatts. As can be seen in the Bing image, these four 53 megawatt generators don’t need a huge building and large crew to operate and monitor them. No wonder the coal powered plant portion was closed as being too expensive to operate.

In 2008, there was a proposal to redo the whole site and replace the existing power generating facilities with a state-of-the-art natural gas fired power generation facility. This 2008 proposal also included an office park, marina and luxury commuter-oriented housing.

This is the April 27, 2012 South Amboy Guardian article announcing the demolition of the plant.

Here is the only information I have found which has some, though not much, specific information regarding the demolition of the plant.

While I don’t have the specifics of what damage was done, Hurricane Sandy from October 2012 knocked out power in the South Amboy & Morgan area for a number of days. I have to imagine the four 53 megawatt generators located next to the bay were drenched by the tidal surge which flooded other parts of South Amboy, Morgan, Sayreville, all communities on the shores of Raritan Bay, as well as New York City.

While I don’t have the specifics of what damage was done, Hurricane Sandy from October 2012 knocked out power in the South Amboy & Morgan area for a number of days. I have to imagine the four 53 megawatt generators located next to the bay were drenched by the tidal surge which flooded other parts of South Amboy, Morgan, Sayreville, all communities on the shores of Raritan Bay, as well as New York City.

Many people probably consider this building to be an eye sore. I certainly used to until I looked at it closely, started to notice its classic architectural features, and gained an appreciation for its attributes. Now I have a better sense of its history and heritage and am feeling that there should be a sense of loss after this building is flattened. I know I’ll have a sense of loss. Perhaps this building would have been able to shield the power generating capability of the plant from a storm like Hurricane Sandy. Wouldn’t it be really kewl if someone with vision was to convert this building from an abandoned power plant to a stylish set of condos overlooking the Raritan River and Bay? They could call it “Power Plant Luxury Condos.”

Many thanks to Diane Norek Harrison for the initial information on the power plant which greatly helped me do the searching of the back issues of the South Amboy Citizen.

Here are the articles from the South Amboy Citizen and the Matawan Journal. Note that not all of the text was transcribed. These untranscribed sections are shown as ellipses. Much of the text in both newspapers contained the exact same text. They must have published press releases from JCP&L. The South Amboy Citizen doesn’t have any back issues from 1953. Thank goodness for the Matawan Journal or I wouldn’t have been able to determine when the plant expansion occurred.

July 18, 1930 South Amboy Citizen

Power Plant Engineering, a leading semi-monthly magazine published by the McGraw-Hill Publications, and devoted chiefly to the interests of the field for which it is named, devotes twelve pages of a July [1930] issue to describing the local project. The project is the leading story of the issue in question under the heading “South Amboy-It’s Different”. There are fifteen photographs of various views taken at the construction site quite recently and seven drawings showing the various layouts. A very complete compilation of data relating to the local plant is given in the story, including the names of the contractors as well as the names of the makers of the various machine sand equipment being put in.

Besides the general contractor, Electric Management and Engineering Corporation, there were thirteen subcontractors employed on the work. The project has been under way now about eighteen months and has not almost reached the stage where the working forces of about three hundred men will begin to be slowly reduced.

The publication referred to devotes an entire column to editorial comment dealing with the new power station. Calling it “the outstanding central station of the year”, the editorial in the concluding paragraph says: “In short, judging South Amboy by present standards of central station design, we feel that it represents a long step forward in the art. The high pressure equipment, as has already been shown, does much to forestall obsolescence and the sound engineering of the details should lead to high operating economy. There is every reason to believe that it will play an important part in the great drive of the industry for more system capacity per dollar of investment. South Amboy, in our opinion, is the outstanding central station of the year.”

Recently a neon-gas sign was erected on top of the highest building. This sign in itself is one of the largest in the state, and certainly the largest of its kind in this section. The sign when lighted up is visible for miles around. Yet it operates on the ordinary house lighting voltage.

The new plant will generate three voltages of current; 13,000; 33,000 and 66,000. These voltages will be transformed by apparatus now being installed to various voltages required for local consumption or distant transmission. Two transmission lines to connect the plant with other section of New Jersey are now in process of construction.

Most of the descriptive matter in the article referred to is quite technical in its reference to the equipment being installed. But in dealing with the station building the article is understandable to the ordinary reader. Under a sub-heading “Station Is Example of Good Architecture” the writer says: Both interior and exterior of the South Amboy station present a most pleasing appearance. As shown in the headpiece, the building design is simple; it is dependent on two principal masses, with good fenestration. The vertical lines of the pilasters, the conservative decoration at the top of each pilaster and the continuous horizontal lines of the stone trim at the top all contribute their parts to the total satisfactory effect.

“The station is of light buff face brick and steel construction. As evident, the wall space between pilasters is practically all window, providing splendid lighting and ventilation.”

“This is especially noticeable in the boiler room where the absence of overhead bunkers permits full advantage to be taken of the windows and the monitor over the firing aisle.”

“The interior of the boiler room is left in the original light colored brick of the building walls. In the turbine room, however, an unusually pleasing appearance is obtained by rows of dark brown tile. The turbine room floor is of brown tile.

“It is evident from the foregoing description that South Amboy plant differs in many of its details from other power plants. Simplicity of operation and high economy with low first cost were the fundamental requirements that determined many of these details.”

“A point of particular interest in the design of the South Amboy station was the close cooperation and interchange of ideas existing between the architects, manufacturers and engineers in the design of this station. The result is an outstanding example of what can be done by utilizing the ability and initiative of those involved.”

August 1, 1930 South Amboy Citizen

At the local project there is now an almost steady stream of trucks engaged in carting sand into the location for filling in purposes. Sand by the thousands of yards, is going in there and long ago the swamp land that used to greet the eye disappeared underneath the covering that is to elevate the whole-area some distance above the high tide level.

It is understood that the project has some time since reached the stage where workmen are being dispensed with a few at a time, because of there being nothing more for them to do. There are still, however, more than a couple of hundred employed on the site.

October 31, 1930 Matawan Journal & November 7, 1930 South Amboy Citizen

The station has an initial capacity of 50,000 kilowatts and an ultimate capacity of 300,000 kilowatts. It embodies many improvements in engineering design and will meet increased demands for service in the metropolitan area serviced by the company including part of the power requirements of the newly electrified Delaware, Lackawanna and Western Railroad.

Governor Morgan F Larson, at the conclusion of the dedication ceremony, threw a switch which formally cut the plant into service. The plant has been under construction for two years and represents an investment of approximately $6,500,000. Upon completion of twenty-six miles of steel tower transmission lines, the South Amboy plant will be connected with Jersey Central’s generating station at Whippany, in Morris County. Seven miles of steel tower transmission lines leading from South Amboy into the southern territory of the company became energized with the opening of the new plant today [10/31/1930].

…

Three hundred men, including State and municipal officials, representatives of industries using Jersey Central service, and many utility men, attended the opening and were guests of the company at a buffet luncheon served in railroad dining cars on a siding within the plant yard. An inspection of the plant followed the luncheon.

One of the features of the new plant is its coal handling equipment. Coal is taken by automatic machinery from the barges on Raritan Bay, conveyed to the power plant, pulverized into powder as fine as flour, and fed to the burners beneath the great boilers, the entire process taking place without manual labor.

Boilers of the plant have also attracted wide interest. They are operated at the high boiler presser of 1,400 pounds per square inch. To withstand the terrific pressure, the boiler drums are forged from single pieces of steel in precisely the same manner used in making heavy artillery. The steam lines are also of the same heavy construction.

Two 25,000 kilowatt turbo generators have been installed to give the plant its present generating capacity of 50,000 kilowatts. These generators are unique in that the high and low pressure units are placed one above the other instead of on the same level as is usually the case. This results not only in greater efficiency for the generating units but also in great savings in space. As the demand for power increases, it will be possible to install a third 25,000 kilowatt unit between the present two. The plant is so designed that additional units may be constructed to bring the ultimate installed capacity up to 300,000 kilowatts.

…

It is making possible the building of a steel tower transmission line twenty-six miles long between our South Amboy plant and our Whippany plant, thereby physically interconnecting our northern and southern divisions. The right of way for about sixty-five per cent of this line has been acquired and the building of the line is one of our major activities for the year 1931.

Looking at the Original 1930 Front Façade of South Amboy’s E. H. Werner Power Plant Building in May 2008. “The vertical lines of the pilasters with good fenestration… all contribute their parts to the total satisfactory effect.”

November 7, 1930 Matawan Journal & November 7, 1930 South Amboy Citizen

Dedication of the Jersey Central Power and Light Company’s new central service station at South Amboy, last Friday must have held several surprises for the distinguished gathering of some 350 invited guests, prominent in public and business life in the 204 New Jersey communities this company serves.

First it furnished a striking illustration of the way communities outside the state’s largest cities, are growing. The plant is capable of supplying electric light and power for 253,000 people, a population about fifteen times that of Asbury Park, and the address of the president, Thomas H. Crumley, showed that its business has increased 95 per cent in five years. Second, the plant is a revelation in the way modern machinery can cut production costs. It operates almost without manual labor. The coal, pulverized to a fine dust, comes into the building and is fed directly to the furnaces, just as water comes into a house, in pipes, without being seen or handled. There are no stokers. The ashes are taken out, unseen, by suction and the slag, heated to a high temperature, turns liquid and runs off in pipes like waste water. Apparently there is no work to be done, except watch the instrument board and answer the telephone, and yet the plant, occupying 450 city lots, is of a size that used to be run by hundreds of men. The coal handled is 175,000 tons a year, enough for a city of 100,000 people. The water consumption is 84,000 gallons per minute, more than the supply of the city of Cleveland.

…

Mr. Crumley sketched briefly the short history of the Jersey Central Power and Light Company. The company was formed in March 1925 and represented a consolidation of eight companies. Since that date twelve other companies have been acquired, most of them during 1926 and 1927.

June 11, 1953 Matawan Journal – Special JCP&L Section

Name New Plant in Honor of E. H. Werner, JCP&L President (Page 1)

…

The E. H. Werner Station, named in honor of the company’s president, in recognition of a lifetime of work in the utility field, was dedicated to “Better Living Electrically.”

…

Following Mr. Reed’s dedication address a bronze plaque commemorating this important milestone will be unveiled by Miss Beverly W. Bell, granddaughter of President Werner. The plaque will be permanently affixed in the new station’s lobby.

The South Amboy plant site, located on the Raritan bay, covers 28 acres, equal to 460(?) city blocks. The original plant first went into operation in 1930 and contained two turbo-generators capable of generating 55,000 kilowatts.

The original building was designed by the architects of the Empire State Building. The new extension follows the same ultramodern architecture.

The addition of the new 62,500 kilowatt turbo-generator more than doubles the plant’s generating capacity and cost $12,500,000.

The plant is designed to burn either coal or oil with an estimated coal consumption for one year, including the new addition, of 270,000 tons.

The power project is part of JCP&L’s $600 million, 10 year post-war expansion program to keep ahead of area growth and customer electric demands in the territory served.

Public Open House Planned for South Amboy Plant Week of June 15 (Page 1)

Visitors to See Electricity Made

The public is cordially invited by Jersey Central Power & Light Company to tour its E. H. Werner electric generating station during the week of June 15-20 to inspect the plant with its new $12,500,000 addition.

The hours designated for public inspection are 2 p.m. to 4 p.m. Guides will be furnished to escort groups through the “home where giants live”, giants being the turbogenerators which whirl round the clock providing mighty strength to turn the wheels of industry and provides comfort and conveniences in homes, schools and business.

The station is located off the Edison Bridge on the Raritan River. Persons coming from the shore regions can stay on Route 35 until they approach the immediate entrance to the Edison Bridge. At this point the highway veers to the right with signs posted for travel to South Amboy. After following this road for approximately one mile, signs will indicate the gateway to the installation. North Jersey visitors can leave the Garden State Highway north of the Edison Bridge and travel over the bridge to another highway marked South Amboy on the right and follow this road to the plant’s entrance.

In the power station, visitors will see the first installation of the cyclone-fired boiler on the eastern seaboard. They will be escorted through the various phases of plant operation from the pile of coal to the final product-kilowatts.

Those attending will see the modern air conditioned switch room and plant, control centers. In these control centers, operators with finger-tip control switches regulate the flow of electricity out to the substation- and transmission system.

They will see huge boilers gobbling up tons of coal in the production of steam, condensers with miles and miles of pipes, three turbo-generators lying side by side with tons of steel spinning in unison beneath their casings.

At one stage of the trip, visitors will have a chance to peek into the raging inferno inside the furnace and observe powder-like coal being blown into-the heat producing center in the initial process of making the steam to whirl the turbine blades.

Open house for employees of the company will be held Saturday and Sunday.

The activities behind the walls of the power plant will be shown in the operations of a normal day — a day of producing electricity, the silent, powerful, unseen genii ready to answer any call by the mere “rubbing” of a switch.

JCP&L Expands Facilities to Precede Community Growth (Page 1)

Jersey Central Power & Light Company’s expansion program since the end of World War II has been consistent with the continuing increased demands for the company’s electric service. The new addition at the company’s E. H. Werner Station has been erected to help stay ahead of the challenge of rapid growth.

The population trends during the 1940-1950 period showed that the local electric company’s service area, comprising all or parts of ten counties in one quarter of the State of New Jersey, had grown twice as fast as the entire state.

Last year, the company experienced a record one-hour peak demand of 225,000 kilowatts of power recorded on Dec. 29, 1952. The previous high in hourly peak demand occurred in December, 1951 and amounted to 207,000 kilowatts.

Development of the company’s market was further accelerated by the total kilowatt hours generated, purchased and interchanged in 1952 amounting to 1,113,830,000 – an increase of 66,710,000 hours over 1951.

Since its incorporation in 1925, the average home served by JCP&L has more than tripled its use of electricity and the average price per kilowatt hour to all users has steadily come down. In 1952, nearly 10,000 new customers were added representing an increase of 5.6 per cent in total number of customers served.

Average kilowatt hour sales per residential customer for 1952 reached 2,149, an increase of 185 kilowatt hours or 9.4 per cent over 1951.

The New Jersey Turnpike and the proposed Garden State Parkway extension are expected to contribute materially to the future growth of communities in JCP&L’s area. Company officials feel that the easy accessibility to the local power firm’s shore and lake regions through these superthoroughfares and the natural advantage of the area should attract more business from metropolitan centers and further accelerate the increased population trend.

New industrial business has been brought to the company’s territory through its industrial development program in cooperation with municipalities. Last year 29 new industries were established in the area and 14 additional industries expanded operations at existing plants.

Approximately 2,300 jobs were created by this industrial activity which will result in on estimated increase of $6 million in annual payroll.

The rapid growth of parts or all of the ten counties served by the electric firm show population count in Morris County in 1940 totalling 116,651 growing to 151,909 in 1950; Ocean, 37,407 in 1940 to 50,289 in 1950; Passaic, 16,783 in 1940 to 25,061 in 1950; Somerset, 4060 in 1940 to 6289 in 1950; Union, 20,029 in 1940 to 34,035 in 1950; Monmouth, 158,618 in 1940 to 227,785 in 1950; Essex, 7624 in 1940 to 24,492 in 1950; Mercer, 7856 in 1940, 9358 in 1950 and Middlesex, 34,998 in 1940 to 46,917 in 1950.

With the future of the area marked with more and more growth, JCP&L is also growing all along the line to meet increased demands.

Years of Detailed Planning, Building Went Into Erection Of Power Addition (Page 1)

Resembling a mammoth jig-saw puzzle, made up of hundreds of intricately shaped pieces, all marked and laid out on the builder’s plan to fall together, the new addition at Jersey Central Power & Light Company’s South Amboy plant began to take shape in 1950.

Steel and mortar blended with the abilities of man and machine now stands as housing for the company’s new huge 62,500 kilowatt turbo-generator. This machine produces the electricity that will help meet the ever increasing demands for electricity in the rapidly growing section of the state served by the local firm.

Several years of planning and actual construction went into the final creation of the edifice of electric production. Long hours spent over drafting boards, reams of engineering calculations, weeks of concentrated study of potential area development and accompanying electric requirements, location of a suitable location for the new addition and consideration of financial hurdles were necessary before the $12,500,000 project could be undertaken.

The decision was made by JCP&L officials to add to the South Amboy plant because of its location in the center of the company’s territory the accessibility to fuel and water and the existence of facilities, including intake discharge for condensing water and an existing coal-unloading tower.

The turbo-generator, requiring three years to complete, along with auxiliary equipment was ordered and the necessary details outlined before the first bite of the crane bucket in the ground would signify the beginning of construction.

A ten-mile maze of pipe work, exclusive of the boiler, had to be put in place for steam and water. Approximately 100 miles of electrical cable was necessary to tie all of the equipment together to form the compact automatic unit.

Concrete, enough to lay a sidewalk from South Amboy to Long Branch, or 6,500 cubic yards was mixed and poured. A 1200 ton coal bunker capable of holding a fifty-four hour supply of fuel was installed. The massive boiler costing $1,300,000 was set into place, with the main drum alone weighing 68 tons. The main drain had to be suspended in position from its overhead supports.

Hundreds of pipes, some over 100 feet long, were attached in the boiler to the upper and lower drums. Each piece of pipe was numbered and calibrated to fit exactly in its proper opening in the drums. Men skilled in boiler construction welded and hammered day after day as the huge boiler slowly took shape.

Air heaters made up of ten thousand tubes, 52 feet and 16 feet long, were scientifically assembled. If laid end to end, these tubes would extend over 68 miles. Brawn and brains wrestled with enormous sections of the turbine generator as they were raised from ground level to the turbine room floor upon piling jacks. These sections were slid into place through an opening in the plant’s wall.

The turbine spindle and rotor, possessing hundreds of precision made blades, was raised by a crane and moved across the plant floor level. It was then lowered inch by inch under the expert eye of the engineers into the recesses provided in the base of the unit-this operation took tedious time and thorough control so damage would not occur.

Extreme safety precautions were followed throughout the construction as workers crawled like ants around the framework of the project. Every joint of weld was X-rayed and every test applied to guarantee the maximum of safety and efficiency of all equipment installed.

After months of painstaking labor, the first test was set for all the equipment to perform together. Coal entered the bunker, fired the boiler created steam which gushed into the new turbo-generator electricity was being made. Enough electricity was produced by the unit in one hour to serve the average residential customer for 34 years.

Another turbo-generator had been assembled, another source of power placed on America’s production line to aid the continued growth of communities served.

JCP&L Plant Crew Lauded For Action during Munitions Blast (Page 1)

Two years ago this month Jersey Central Power & Light Company’s South Amboy electric generating station was shattered by a tragic munitions explosion. Today it stands proud and strong on the banks of the Raritan River as ceremonies are being held to name it after the company’s president, E. H. Werner, pioneer in the power field, and dedicated to “Better Living Electrically.”

Fifteen JCP&L shift workers were on duty the fateful night 600 tons of munitions loaded on a barge ignited 550 yards from the plant causing the death of 31 dock workers.

Some 2300 live anti-personnel mines were blown into the plant and on its property. Collapsed walls and twisted steel posed additional hazards.

Although many of the men were injured and in deep concern for their families, in the stricken area all stuck to their posts and shut down the plant to prevent further damage. The electric load was maintained to the crippled city without interruption.

…

The station was damaged by the devastating force of the explosives but soon was restored to operation and further expanded, another example of man’s ability to fight back.

Looking East toward the E. H. Werner Power Plant in May 2008. “The vertical lines of the pilasters, the conservative decoration at the top of each pilaster and the continuous horizontal lines of the stone trim at the top all contribute their parts to the total satisfactory effect.”

Safety Pays Off (Page 1)

Although it took a little over two years to build the former portion, of the E. H. Werner Station and approximately three years for the new addition not a single fatality occurred during the construction phases of both sections.

Not only were there no fatalities during the construction of the old and new sections of the plant but the disability accidents which occurred were held down to a minimum number.

Story of Electric Production Begins Far Beneath Earth in Piece of Coal (Page 1)

A now giant turbo-generator hums quietly in the $12,500,000 addition to Jersey Central Power & Light Company’s E. H. Werner station which helps produce electricity ’round-the-clock for the needs of 185,000 customers in the company’s territory. The origin of the operation goes deep into the earth to a piece of coal.

Before the coal begins the transformation to kilowatts, it must be dug from mines and shipped to the power station. There it goes through a pulverizing process for two of the plant’s three turbine generators where it is ground into a fine talcum-like powder.

From the pulverizing mills, the powdered coal in blown into huge furnaces lined with literally miles of water filled tubes. The heat from the burning coal changes the water in the tubes into steam. For the new 62,500 kW turbine-generator at South Amboy the coal doesn’t need to be pulverized, but is crushed to one-quarter of its size in comparatively simple crushers.

The energy packed steam is then passed at very high pressure and temperatures as high as 1000 degrees into the turbine making it whirl at great speed – equal to 600 miles per hour.

The steam blows at 1200 miles an hour against curved blades in the turbine called “buckets” at an intensity of 12 times that of the velocity of a hurricane.

It goes through approximately 20 feet of buckets and nozzles in a split second. In this 20 feet it passes through from 17 to 20 turbine wheels, an equal number of nozzles and pushes against some 5000 buckets. The rotor, while spinning at such great speed, turns the generator which builds up an electric pressure in the copper coils of the stationary part of the generator, forcing electrical energy over miles of wires to homes and businesses.

Electricity is delivered from the power station plant to various substation distribution points through a vast network of power lines ranging from 2,400 volts to 115,000 volts. To cover the 1,520 square miles of JCP&L service area nearly 20,000 miles of wire, 175,000 poles and 63 (?) substations are required.

Practically all of the electricity furnished by the local electric company is produced in its three major plants at Whippany, Raritan River and South Amboy. The company also maintains interconnections with other electric utilities for interchange of power.

The combined output of company owned plants last year was 1,113,783,000 kilowatt hours or enough electricity to supply the average home served for over 518,000 years.

Electrical energy cannot be stored. There is no reservoir to draw from except the generator itself. The equipment must be so maintained as to be capable of delivering the highest combined instantaneous demand of all of the customers with enough reserve to cover any emergency.

The new addition at the South Amboy station is as modern as tried and proven method of operation can make it. When the need for power is instantly sensed, automatic equipment controls the supply of steam to the turbo-generator by increasing the flow of coal, air and water enough to make the added electric energy needed.

The coal to kilowatt story is as gigantic as it is fascinating. The final chapter is dedicated to supplying electric power for better living.

Text Under the Photo of Generators (Page 1)

GIANT POWER MACHINE: The new 62,500 kilowatt turbo-generator at Jersey Central Power & Light Company’s E. H. Werner power plant towers above the operator on the right. The mammoth machine more than doubles the plant’s generating capacity and is the “grand daddy” of the other two machines seen in the rear section of the turbine room floor. The huge power producing units weighs 745,000 pounds. It is the second power plant addition completed by the local electric company since 1945 with another scheduled for 1955 designed to help produce power to pave the way for future area development.

E. H. Werner Leader In Power Field (Page 1 & Page 4)

E. H. Werner Leader In Power Field (Page 1 & Page 4)

A leader in the electric industry will be honored tomorrow at South Amboy. In the naming of the electric generating plant of Jersey Central & Light Company after E. H. Werner, president of the company, time turns back over 41 years to the beginning of the executive’s utility career.

Mr. Werner was born in Wernersville, Pa., a town named in honor of his grandfather, who settled there shortly after the American Revolution. He entered Pennsylvania State College, State College, Pa., where he obtained his engineering training.

Upon graduation in 1909, he assumed his first position as a draftsman.

In 1912 he joins Duquesne Light as an engineer, also serving as engineer for the Pittsburg Railway Company.

Three years later, he entered Reading Transit & Light Company as chief engineer. He became president and general manager in 1929 and helps reorganize the company and form its subsidiary, the Reading Coach Company.

In 1933, Mr. Werner became vice president and general manager of Metropolitan Edison Company, Dover. He retained these posts with both companies until 1936 when he relinquished his position held in NJP&L.

Within five years, the official assumed the presidency and general manager’s post of Pennsylvania Edison Company and Blair Engineering & Supply Company of Altoona – the latter a subsidiary of the Pennsylvania Edison now Pennsylvania Electric Company.

Mr. Werner came to the shore power company in 1945 as president to succeed the late Thomas R. Curmley. In addition to his managerial duties he is active in Red Cross, Community Chest and other civic projects. Among his many civic duties, he serves as a member of the Board of Governors of Fitkin Hospital, Neptune.

Facts about the E. H. Werner Station (Page 2)

The station is centrally located at South Amboy at the mouth of the Raritan River, adjacent to rail, highway and water transportation of fuel and supplies.

The original station, first high-pressure steam plant in the East, went into operation in 1930 and contained two units capable of generating 50,000 kilowatts, Later this was increased to 55,000 kilowatts. Total cost of the original station was $6,000,000. The new addition cost twice that figure.

Expansion of the original plant includes an addition to the former building to house a new 62,500 kilowatt turbo-generator of the latest design; Cyclone furnaces, pressurized boiler and its auxiliary equipment; and new coal-conveying and crushing system. In effect, it’s a new plant added to the original station.

The turbo-generator operates at 1650 pounds per square inch steam pressure and a 1000 degree F temperature.

The steam generator has a capacity of 475,000 pounds per hour. It is fired by two Cyclone furnaces, first of this type to be installed in any power plant in the east.

As with other power plants operated by JCP&L, the E. H. Werner station is tied-in through a vast network of power lines with other sources of power, ensuring a constant supply of low-cost electricity for homes and business.

The Four Smoke Stacks of South Amboy’s E. H. Werner Power Plant in May 2008. There is Something Charming about the Three 1930’s Era Smoke Stacks.

New Addition Uses Supply Of Own Power (Page 3)

The new addition to Jersey Central Power & Light Company’s E. H. Werner electric generating station, South Amboy, will use some of the additional electric energy the 62,500 kilowatt power machine will produce.

Lights, motors and other electrically driven equipment used in the operation of the plant require large amounts of electric power to operate them. Throughout the new addition are a large number of electric motors which range in size, from 2000 horsepower down to the 2-watt electric motors in the plant, clocks.

Large motors operate the boiler feed pumps in the basement of the plant. These pumps force water to the boiler tubes against terrific steam pressure and circulate millions of gallons of water every day. In 26 minutes, the pumps will circulate enough water for the daily consumption of a city of approximately 17,000 persons. Other motors operate forced draft fans which supply air for the cyclone burner.

Other motors perform the functions of conveying the coal and crushing it, operating other water and oil pumps. Machinery in the repair and maintenance shop consume electric as well as elevators and other miscellaneous equipment.

The power used in the plant must go from the generator to the substation and be converted in the right voltage for plant use and returned via wires as in any other manufacturing plant.

E. H. Werner Plant Largest In System (Page 3)

Allenhurst electric producing plant had the distinction of being the largest station, owned by Jersey Central Power & Light Company 25 years ago with a capacity of 14,000 kilowatts. Today, the E. H. Werner Station rated at 117,500 kilowatts has this honor with the new addition-more than doubling its former capacity and making it the largest plant in JCP&L’s system.

The company’s two other electric generating stations located at Whippony and Sayreville have rated capacities of 20,000 and 100,000 kilowatts, respectively.

Three Shifts Operate Station 24 Hours Day (Page 4)

Operations at the E. H. Werner electric generating station of Jersey Central Power & Light Company go on 24-hours a day under the experienced management of men skilled their respective duties. The overall operation of the station is under the supervision of John E. Casey, Sayreville plant superintendent.

Assistant to Mr. Casey in managerial duties is George Roome, Freehold. J. R. Ketchel, Matawan, general superintendent of production, with offices located in the E. H. Werner power station, supervises power production in all of the company’s three major plants. George Ritter, Matawan and Elmo Stewart, Lakewood, perform the duties of assistant to the general superintendent of production.

On each eight-hour watch there is a shift foreman who has charge of directing operations of boilers and generators, and all other duties connected with the generation of electricity. Each shift foreman is in full charge during his time on duty. The plant operates in three eight hour shifts during the day as generation is continuous during the entire 24 hours.

The shift foremen at the plant are Robert Maney, Fords; Arthur Ogborne, South Amboy; Percy Tompkins, South Amboy; Joseph Loy, Morgan and Alfred Eckman, Keyport.

A plant maintenance crew headed by Norman Nelson, Morgan, assisted by Leslie Moore, South River, carry on all repair work. This work includes regular maintenance, emergency repairs and turbine overhaul jobs.

Electrical work at the plant is under the supervision of Clarence D. Graw, Helmetta, electric maintenance foreman who has charge of all electrically driven machines, the plant lighting system, electric controls and is responsible for sub-station maintenance and other equipment.

Work of handling the mountainous pile of coal stored at the plant is under the supervision of Howard Wray, South Amboy. His duties include receiving the coal, properly storing it and making sure a steady supply is brought to the crusher.

There are 109 other members of the various crews, who know their jobs like clock work and keep trained eyes and skilled hands daily on the controls of plant production.

These men work together as a team and react together as one in the job of producing electricity for the needs of the communities served.

Proper Planning Maintenance Keynote (Page 4)

Maintenance needs in Jersey Central Power & Light Company’s electric generating stations require a well-organized department and immediate planned action, proper planning being the keynote to good maintenance.

A preventative maintenance program coupled with constant inspections of equipment and able crew members to meet the problems are the backbone of the department.

Inspections are set up on a weekly, bi-weekly and monthly basis. Reports are filed in writing covering any conditions that are detected. The reports are studied by supervision to determine the seriousness involved. Job orders are then made out for minor repairs.

To help guard against any oversight, different personnel are assigned to the inspection procedure each week.

When an overhaul of a piece of equipment is necessary, the first consideration must be when to take the equipment out of service. The work may be done at midnight or over a weekend depending on the importance of the project and when the equipment can be taken out of service. On larger overhauls, the men are split into crews so that the job goes on around-the-clock.

Along with the planning and preliminary work, a very important factor is well-trained men, who know how to meet emergencies in their stride.

To further speed things up it is necessary to have good tools in first class condition. Each man is issued a kit of tools which are his responsibility. These tools take care of his needs on small jobs. A tool crib is operated to provide tools not carried in the assignee kits. Special tools of all kinds are available to men in exchange for a tool check which is returned to the man upon return of the tool. All rigging must be at his disposal for time is the important item. Heavy equipment which is needed on a job is on wheels so that it can be moved quickly.

The problem of storing these tools and equipment becomes a large one. Each tool, chain block, ladder, torch, wrench or other equipment has a designated, place and must be kept there when not in use. A job is not completed until the equipment is again available for service, the tools put away and the area cleaned up. In this way equipment is easy to find and the “house kept in order.”

Maintaining a power plant is a gigantic operation. Most all repairs are made by the maintenance forces and a very small percentage is sent out. The only repairs made outside are on pieces of equipment too large for plant machine tools to handle.

No matter how big or how small a job, the maintenance forces in JCP&L’s power stations move swiftly and expertly in helping to keep electricity flowing.

JCP&L Dedicates E. H. Werner Station

… Philip Reed, chairman of the Board of Directors of the General Electric Company said at a dedication ceremonies held Friday [June 12] at JCP&L’s E. H. Werner Station, South Amboy.

… the new $12,500,000 addition to the power station…

The E. H. Werner Station, named in honor of the company’s president, in recognition of a lifetime of work in the utility field, was dedicated to Better Living.

Mr. Reed said it was no accident that America, with only seven per cent of the world’s population, produces nearly 40 per cent of the world’s goods and, generates nearly 40 per cent of the world’s power. This electric generating capacity was put in place by the private electric utilities of this country who have kept ahead of electric requirements, Mr. Reed said.

“The availability of power must precede the use of power, and in Jersey Central Power & Light Company you have one of the foremost architects of just that kind of progress,” the G.E. executive said.

“Under Mr. Werner’s leadership, which embraces the postwar expansion period, JCP&L has added 140 per cent more generating capacity to meet the requirement of the great community it has served so well through the years,” he continued

A bronze plaque commemorating the dedication was unveiled by the utility president’s granddaughter, Miss Beverly Bell. Referring to the plaque, Mr. Reed said it was a “salute to and a symbol of E. H. Werner, the man, and the company he keeps.”

Mr. Werner, in acknowledging the tribute by Mr. Reed, said the glory deriving from the dedication ceremony must be credited to the entire Jersey Central Power & Light organization. He praised employees, officers and directors of the company for the splendid teamwork and cooperation.

“It is most fitting that this station should be dedicated to Better Living,” Mr. Werner said, “for electric power has played a vital role in relieving drudgery in the home, on the farm, in the factory and in business—in fact, electric power has brought about the greatest standard of living in the world.”

…

Originally posted on October 14, 2012.

I have pictures of Joseph Loy and Norman Nelson, who are both mentioned in your article. If you would like to see them or are at all interested, please let me know. I will be more than happy to share them with you.

I have been taking pictures of this building since 2008, all from the train. I’ve been attracted to the beauty of this building, and then one day I noticed that the windows have a white cover. I thought something was wrong, and little by little I realized that the building was doomed. I just felt the insensitivity of, who else?, developers, that they only understand of profits. Now, reading this article I learned that the building was designed by the same architects that build the Empire State, and that is something that added sorrow at the sorrow I already felt.

Thank you for compiling all this information about this beautiful jewel.

The building is nearly gone now I’m told. Very sad in some ways. Not sure what, if anything, will go on that location.

My father, Ted Hermans, had just gotten home from working his shift at the Warner Station when the “Powder Pier” explosion occurred. We lived in Old Bridge, and felt the explosion there. I remember the soot being blown into the house from our pot belly stove exhaust pipe.

Upon learning where the explosion was, my father immediately got back into his car and went back to the station to help.

Thanks for the info. That must have been quite an experience. Guess your father determined that the explosions would have come from the pier because of the types of things which were loaded there?

The men who worked thru the explosion and ultimately shut down the boilers and tunbines were awarded th Claude L Mathews award for valor for their bravery.

My grandfather worked in the plant until his death, i’m not completely clear in what area he worked. My mother told stories of going to the plant and fishing off the pier during his off hours. I spent a sizable amount of my life looking at the building and always wondering what it was like inside. I’ve seen both color and black and white photos of the interior. They simply blew my mind. I’ve lived in south amboy all my life and the history of the town always intrigued me to where i always look for something new. Thank you for putting this all together to share with us.

Do you have any newspaper articles of the employees awarded the Claude L. Mathews award? My grandfather may have been honored. Edward South

Thank You

Sorry, I have yet to see any articles on this.

Excellent Research and photos ! I worked at the RR towers in South Amboy and later Morgan Draw, so this plant was very familiar to me. Back when eastbound PRR and then PC coal trains were common into South Amboy Yard to service the plant, before the changeover to oil. THX

Thanks, Bill! Would love to get some stories from you or scans/images of any photos/memorabilia. Thanks, Verne

I have an interest in Power infrastructure and wanted a closer look to photograph the site. The current Google map images still shows the four oil turbines. When I got there they hade been removed. One of the turbine units was still there without the housing which was pretty cool to see. You might be interested in the photos. https://shoregrafx.smugmug.com/South-Amboy/E-H-Werner-Power-Plant-South-Amboy/

I was stunned when I read “Three Shifts Operate Station 24 Hours Day (Page 4)” to see my maternal grandfather John E. Casey of Sayreville mentioned. Sadly, he passed away in 1956 when I was 2 years old so I never had a chance to get to know him. My dad (his son in law) always told me that he was “one of God’s finest” and one of the most interesting persons to know and to talk too. Thank you very much for this wonderful article!

Dear Sir or Madam

Hi, This is Saksit Pholmana, analyst at PTT public company limited from Thailand.

I am contacting you for the following reason. I would like to ask you a permission to use your image of Power Plant in South Amboy for illustration of our infographic. The infographic will be used for news update regarding energy technology around the world.

(The image was captured from this link : https://www.morgan-nj.org/blog/contentdir/uploads/2013/07/SA-JCPL-from-SI.jpg)

If you have any questions, please do not hesitate to contact me.

Best Regards,

Saksit Pholmana

Analyst

Hi, Please go ahead but also please provide credit for the image and also please send me a link to the finished product. Thanks! Verne James

July 15 1930 Power Plant Engineering can be found here:

https://archive.org/details/sim_power-engineering_1930-07-15_34_14/page/n1/mode/2up

Thanks, Steve! Who knew that it was so high tech for it’s day?